Robust Parts for Battlefield Conditions Produced by Unique Technology

Replacement parts for military systems are usually ordered from warehouses thousands of miles away from the troops, only to wait weeks for them to arrive. 3D printing technology, also known as additive-manufacturing, has become an efficient way to produce the missing spare parts. However, the parts should not only be cost-effective and rapid to produce but also accurate geometrically and have mechanical properties that are sufficiently robust to survive conditions in battle.

Replacement parts for military systems are usually ordered from warehouses thousands of miles away from the troops, only to wait weeks for them to arrive. 3D printing technology, also known as additive-manufacturing, has become an efficient way to produce the missing spare parts. However, the parts should not only be cost-effective and rapid to produce but also accurate geometrically and have mechanical properties that are sufficiently robust to survive conditions in battle.

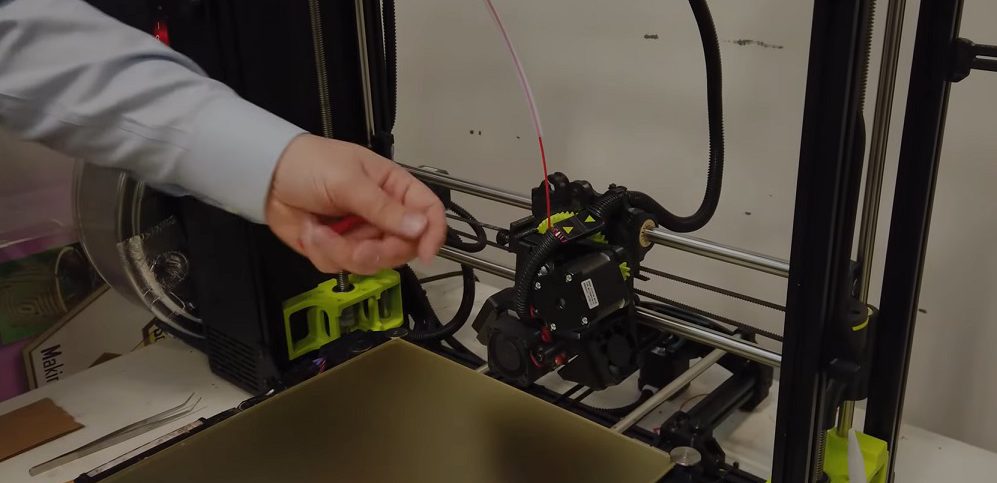

U.S. Army scientists have developed a new 3D printing technology to help soldiers quickly swap out broken plastic components with durable replacement parts.

The team from the U.S. Army Combat Capabilities Development Command Army Research Laboratory (ARL) developed 3D printing method for dual-polymer parts, allowing soldiers to swap out broken pieces and head back to the fight within hours.

For the first time, this cutting-edge filament is capable of being used in off-the-shelf, low-cost 3D printers to produce mechanically strong, battlefield-ready parts.

Dr. Eric Wetzel, ARL’s research area leader for soldier materials said: “We’re crossing a threshold where low-cost, easy-to-operate and maintain printers will be proliferated on the battlefield — and able to produce engineering parts of very good quality with short turn-around times.”

No comments:

Post a Comment